rubber flooring

Rubber flooring is used to secure the ground surface. In the past several years, this product has been able to make gyms, kindergarten centers, sidewalks and urban furniture safe and of course beautiful. Iran Rubber Flooring Company, with modern equipment and expert personnel, has been able to produce diverse and high-quality products and has established a good name for itself among manufacturing brands.

Rubber flooring or granular flooring?

Rubber flooring is also known as granular flooring. Which is known by both names in the market.

Which is really true?

Rubber flooring is produced in a multi-step process that we explain below. In this production cycle, car tires are turned into small grains called rubber granules. Therefore, both the name of rubber and the name of granule can be attributed to it. Although in both cases the name used is correct.

But the important issue is that many times it has been seen that the seller abuses both names to sell his product more expensively. That is, for each of the rubber or granular names, it mentions a special feature and the user considers each one unique. Although there are different types of rubber flooring with non-sports applications, rubber flooring or granular flooring is only meant to secure gyms , children’s playgrounds , urban furniture , etc. , which do not differ in terms of production materials.

The price of rubber flooring

The price of rubber flooring depends on several factors. In general, price should not be the basis of choice because price should be compared to quality. There are many brokers who stand between the customer and the manufacturer and force the manufacturer to lower the price of their product as much as they can. The producer will also have no choice but to lower the production quality because he must be able to adjust the cost of his consumables with the mandatory rate. And on the other hand, brokers tell the customer about the quality of their work. Therefore, the very high price and the very low price of rubber flooring should not be used as a good basis for choosing. After all, the price of standard rubber flooring will depend on the quality of the granules and the quality of the glue and paint used. For example, the price of truck tire granules is higher than the price of passenger cars. Or glue with less solvent has a higher price than the price of glues that are full of solvent. Or mineral paint is cheaper than organic paint. All the mentioned items determine the price of rubber flooring.

Types of rubber flooring

![]() Rubber floorings are produced in various shapes and dimensions, and these differences distinguish its applications. The major differences in flooring can be listed in the thickness, dimensions, bottom surface, surrounding environment and execution method. The types of rubber flooring are listed below. You can choose any of them according to your application .

Rubber floorings are produced in various shapes and dimensions, and these differences distinguish its applications. The major differences in flooring can be listed in the thickness, dimensions, bottom surface, surrounding environment and execution method. The types of rubber flooring are listed below. You can choose any of them according to your application .

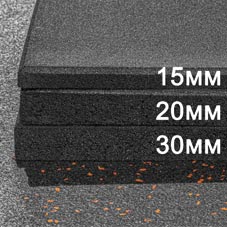

15 mm flooring

20 mm flooring

25 mm flooring

30 mm flooring

40 mm flooring

base covering

groove flooring

flooring thicker than 40 mm

half-meter flooring

puzzle flooring

roll flooring

in-ground flooring

15 mm rubber flooring

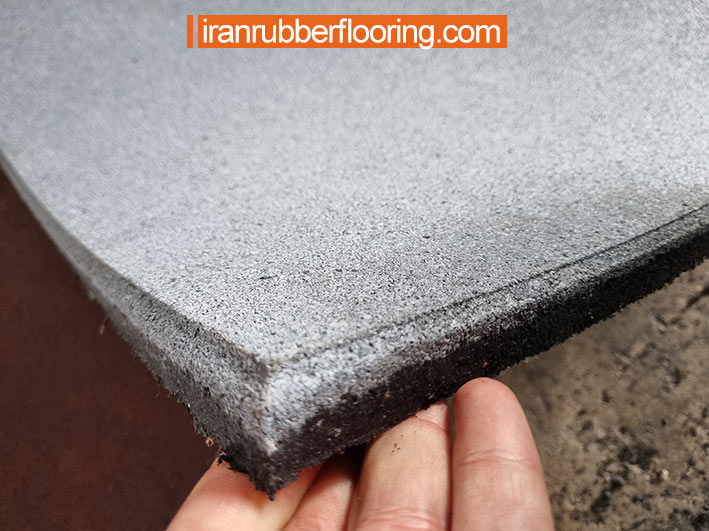

15 mm rubber flooring is the first Tile product. Many gyms request thicknesses less than 15 mm. But the thickness of less than 15 mm should be produced as rolled flooring. And its production in tile flooring is not reasonable. The thickness of 15 mm is made from 5 mm of colored granules and 10 mm of uncolored (black) granules. Therefore, the minimum thickness that can be produced by maintaining the standard for rubber flooring and of course the tile type is 15 mm thick. 15 mm rubber flooring is very popular in gyms. Although you can use a thicker type. But until now, the 15 and 20 mm type has been the most ordered for bodybuilding and office areas. In the gym, the floors are usually black or gray in one color, although using 2 different colors in a checkered pattern will also be very stylish. An important suggestion is that if your gym is located on the ground floor, you can Use 15mm rubber flooring. But if your club is on the upper floors of the complex, using 15 mm rubber flooring is not very suitable. Because 15 mm thickness is only shock absorbing for rubber and cannot be a good insulator for percussion sounds. Due to the suitable weight of 15 mm flooring, it is also very popular in kindergartens and schools. Of course, 15 mm flooring can be used for the yard as well as inside the complex. In general, the uses of this product are very wide, and you can read detailed descriptions on the page of 15 mil rubber flooring.

20 mm rubber flooring

The most common flooring. Among the mentioned cases, the thickness of 20 mm is the most ordered, which is mostly used in body building and fitness clubs. Of course, 25 and 30 mil thicknesses are also used in these gyms, but 20 mil thickness is more preferable due to its more reasonable price. And of course, we suggest that if you intend to buy for halls where ball sports are held, you should use the 20-mil type. 20 mm rubber flooring makes the ball have a good speed after hitting the flooring.

25 mm rubber flooring

although 25 mm rubber flooring is the first choice of sports halls, but 25 mil rubber flooring also has a special place in gyms. So that the choice of many after hearing the features and price is only 25 mil thickness. Of course, it goes without saying that as the thickness of the flooring increases, its price wil l be more affordable. Because the surface of the floor covering, which uses finer paint and granules, is constant in all thicknesses. Increasing the thickness is done with raw and thicker granules. Therefore, the price of thicker rubber flooring is cheaper than thinner flooring.

30 mm rubber flooring

customers are mostly Georgian and Turkish. Most of their orders are 3 cm thick and they rarely order other thicknesses. As mentioned, the price of 30 mil thickness is much cheaper than 20 and 25. Of course, the price should not be the basis of choice because the higher thickness causes more elasticity of the granules. Therefore, walking or exercising on the 30 mil flooring will be more enjoyable than its thinner counterpart. And of course, the sound insulation property will also increase in the flooring. Therefore, 30 mm rubber flooring is a very suitable option for those who like it.

40 mm rubber flooring

with a thickness of 40 mils or more. The 40-millimeter type is a smooth floor with much better features than the 30-millimeter one, and it is used in halls with jumping activities. Such sports include body building, yoga, trx, gymnastics and aerobic sports for which the 40-mil type has a specific application. In fact, the elasticity of the 40 mm flooring is quite noticeable and makes it significantly different from other thicknesses. It is recommended to choose 40 mm of the half-meter type when ordering, because in addition to beauty, it will be easier to install compared to one square meter.

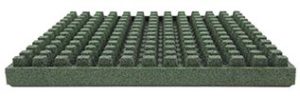

Base rubber flooring

The minimum thickness of this type of flooring is 40 mm or 4 cm. Base rubber flooring is produced in thicknesses of 40, 45, 50, 60 and 70 mm. From the mentioned thicknesses, 23 mm is the height of the base and the rest is the thickness of the flooring surface. Due to the presence of the bases in the lower surface, this product has channels that provide the passage of water caused by snow and rain or washing. Base floors are used for outdoor environments. These environments include children’s playgrounds, health sidewalks, or office and school yards. It is suggested that if you live in a city where there is a high chance of rain, you should definitely use rubber flooring with a base.

Grooved flooring

Maybe you live in a country with little rainfall or the probability of washing the yard floor is very low, in this case there is no need for a floor with a base. But the possibilities should not be ignored either. Because in any case, there is a possibility of water (however small) passing in the ou tside and the yard. So what is the solution? Perhaps there is no longer a need for long foundations or deep gutters, but with a little change in the smooth floor, grooves can be created so that if the water flows in the yard, it will pass under the flooring and it will not wear out the flooring due to its long durability. With this hypothesis, the grooved flooring was produced after the foundation. This flooring has rhombus or cross grooves and determines the passage of water. Although it doesn’t have very deep channels, but as we Iranians say, There is no fault in working hard

Flooring thicker than 40 mm

The majority of orders. Each of the thicknesses has its own unique characteristics and it is not recommended to use them interchangeably. But the floor coverings are also produced in thicknesses greater than 4 cm, which have their own use. In general, thick rubber flooring is a very good insulator for moisture and temperature. In fact, orders for thick flooring are made when there is a need for insulation to isolate moisture and temperature. Now, as the thickness increases, your insulation will be better

Half-meter rubber flooring

although the production of one square meter flooring has a large share in the annual production per capita, but half-meter customers are also very fanatical in their choice. Perhaps the advantages of the half-meter rubber flooring, which will be explained later, have made it difficult to choose the onemeter type. In any case, our recent years of experience show that tastes have tended towards halfmeter dimensions. Therefore, we were forced to pay special attention to half-meter products and to solve the problems that existed before in the production of half-meter floors. The detailed description of this flooring and the solution to its previous problems are stated in the half-meter rubber flooring page.

In short, the advantages of half-meter flooring are:

• More beauty

• Enlargement of the gym

• Easier installation and assembly

• Simpler maintenance

• More maneuverability in the layout

Puzzle rubber flooring

This flooring has a puzzle environment like tatami flooring that locks together during installation. For this reason, each of the puzzle floor tiles lock each other and prevent possible movement of each other. This is the biggest advantage of the puzzle. However, according to many customers, bea uty should also be added to the advantage of this flooring. Puzzle flooring is also produced in two models, one meter and half meter. Like other flooring, it is possible to produce in various thicknesses. Puzzle flooring is also produced in various thicknesses, of which thicknesses of 20, 25 and 30 mils are very common. Puzzle flooring also has its own advantages and disadvantages, which you can find out about on the puzzle rubber flooring page.

Rolly rubber flooring

If you want a floor that has the least grooves possible, then Rolli flooring is suitable for your taste. Rolled flooring is produced in dimensions of 10 square meters and is installed like carpet in sports halls. The background and design of this type of flooring is mostly speckled and silver, yellow and ocher colors are the most popular. Due to the different production of rolls compared to tiles, it is possible to produce them in thicknesses of 2, 4, 6, 8, 10 mm and of course higher. In the roll flooring production process, black and colored granules are first mixed with glue and then poured into press barrels. After applying pressure, heat and specific time, it will turn into granulated sausage. Then the granulated sausage is placed on the roller cutting machine and cut into the desired thickness. Read the pros and cons of roll flooring on the roll rubber flooring page.

In-place rubber flooring

although the roll flooring has been able to solve the problems of the grooves between the tile flooring and create a unified surface, but it cannot be used for roofless and free spaces. Therefore, in such environments, materials are poured on the floor and run. Therefore, the production equipment should be moved to the construction site and the production and installation work should be done there at the same time. This method of production of flooring is called in -ground flooring. One of the main advantages of Dejariz is the integrity of the flooring, and it will also be possible to create a variety of beautiful shapes on the flooring. For this reason, if you need a volleyball and soccer field, or if you plan to build a playground for children, this is the right product for you. Because it is possible to create sports ground lines or beautiful shapes that are beyond the scope of other floorings. You can read more detailed descriptions in Dejariz rubber flooring.

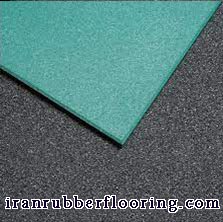

The coloring of rubber flooring

The range of color and of course the quality of color in production, is very important. Floor coverings are distinguished by color. That’s why color variety is very important in choosing. Of course, colors should be used that are durable and not damaged by sunlight or sports activities. The colors used in rubber flooring are powder type. And the powder paint is available in 2 mineral and organic models.

And each of them has its own characteristics. In any case, the color must have the necessary durability and be the same color delivered to the customer as he ordered before. Iran Rubber Flooring Company produces floor coverings using the best pigments in the market that have already passed their test. So don’t worry about the color quality. The flooring will be produced with the quality and color of your choice.

Dotted rubber flooring

in addition to monochromatic flooring, production can be done in polka dots. In this model, the granules are painted and then dried. Then, during production, they are placed in the press tray with new granules. Finally, a floor with colored spots is produ ced. In recent years, this type of flooring has received much attention. Therefore, it is produced in various colors. Spots such as silver, ocher, yellow, green and blue which are very stunning. Of course, colored spots can be placed on the bed of other colors except black, which will double its beauty. Khalkhal flooring can be produced in both tile and roll flooring. You can see all kinds of moles on the molex rubber flooring page.

Thickness of rubber flooring

As mentioned, floorings are produced in various thicknesses. Also, the mentioned thicknesses can be produced at the level of one square meter or half a square meter. Of course, the more the thickness of the flooring increases, the more the elasticity of the flooring increases. So you can achieve higher hit percentage (hic certificate) and safety. Regardless of the surface of the flooring, thicknesses of 20 to 30 mils are used for gyms located on the ground floor and kindergarten or school yards. Thicknesses higher than 30 mils are mostly used as floor sound absorbers.

Floor coverings with any thickness produced had a constant weight per millimeter. For example, in the dimensions of one square meter (or 4 pieces of half a meter), we will have a weight of one kilogram for each millimeter of thickness. It means that a standard 20mm floor will weigh 20kg. Because of this, the weight of the flooring will be one of the important factors for measuring the quality and compactness. Of course, this equation is different for base floors due to the existence of water channels.

![]() 4 common mistakes in choosing flooring

4 common mistakes in choosing flooring

If you are planning to buy rubber flooring, avoid 4 common mistakes. Most of the complaints are due to one of these 4 things, which unfortunately many manufacturers do not pay attention to.

1)The dimensions of the flooring should be smooth.

The first and most important problem is that the sides of the flooring are not smooth. Such a problem will occur if the production flooring is produced quickly. As mentioned, the floor covering is produced at a temperature of 170 degrees Celsius. After leaving the flooring from the production machine, a suitable time should be spent to remove the generated temperature from the flooring. This problem arises exactly at this stage. If the floor coverings are piled on top of each other as soon as they come out of the machine, their high weight will change their shape. For this reason, at least one hour should be spent cooling the product before placing the flooring on top of each other. The resulting problems cause the floors to not be placed exactly next to each other during installation and create a gap between them.

2 ) Falling of granules

The second problem of falling of granules. This problem arises due to the low use of glue in the production of flooring. The price of glue is an important factor in determining the fin ished price of flooring. The less amount of glue is used in the flooring, the faster the granules break apart and the flooring wears out. Therefore, we suggest that you get your product from companies that are reliable and stable and do not sacrifice quality for the price. Because this problem cannot be recognized at the first moment and happens over time and during use.

3) The thickness of the flooring

The thickness of the flooring can also be a solution for the lack of work of some manufacturers. In fact, some manufacturers who work with flooring dealers are forced to use less materials (glue or granules) in order to make the price cheaper. In this case, you will receive a smaller thickness of the flooring that you order. To avoid this mistake, we suggest that you visit the production workshops or make your purchase in person.

4 ) flooring color

The fourth most common problem is poor quality floor color. It is possible for you to buy offline or on social networks. In such cases, dealers will send you pictures of colorful and attractive floor coverings, if you do not receive the desired color on the delivery day. For this reason, we suggest that you play with reliable factories before signing a contract and confirm your purchase.

Summary of rubber recycling

Rubber flooring is a recycled product of car tires. Worn tires are collected and transported to the factory.

Truck tires are first cut into smaller pieces. Finally, the tires are transferred to the Schrader machine by a conveyor belt.

In the Schrader machine, the tires pass through the teeth and become crushed into small pieces called rubber chips. This process is done in several stages and in a closed cycle.

Until the wire or thread is separated from the tire and ready for the next step.

In the next step, it passes through the rolling machine and the wires are completely separated from the tire.

The final product enters the magnet stage. There are two conveyor belts. A transmission belt and a magnet belt that cross each other. The magnet belt absorbs all the existing wires, and the wire-free chips are transferred to the next step.

Now it’s the turn of the separation sieves to filter the available yarn and polyester. The serand part, which is done in 2 stages, is a vibrator device.

Vibrator devi ces make the thread separate from the rubber grains and come out as granules. The produced granule seeds are poured into the bag to enter the granule floor production line in the next step.

How is rubber flooring produced?

In the production of rubber flooring, rubber granules and polyurethane glue are used. How to produce granules that was explained.

Polyurethane glue is also produced by mixing ISO and poly and some other materials.

The production of rubber flooring is done in such a way that the granules are first poured into the mixer. Polyurethane glue is slowly added to the granule while mixing.

The mixing of glue and granules will continue until the glue contains the granules. Of course, if colored flooring is produced, you can also add the desired color.

The colored and adhesive granules are poured into graduated containers and transferred to the press machine.

There, they are poured into the trays of the press machine and spread on the tray by the operator. The press machine is hydraulic and has 2 or 4 trays.

Each of the trays, which have various shapes and dimensions depending on the type of production, are placed between two jaws, both of which are heated by the hot oil system.

In short, the adhesive and dyed granules are cooked in the press machine for 6-10 minutes (depending on the required thickness) and a pressure of 200 tons and a temperature of 170 degrees Celsius.

After it is cooked, it is removed from the machine and placed on a wooden pallet. It should be noted that it takes at least 24 hours for the floor heat to dissipate.